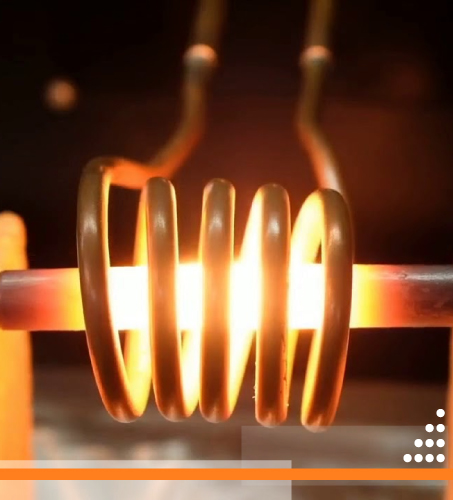

We are experts in a wide range of projects and we have positioned our teams in

large industries, therefore we offer you our knowledge in the manufacture of

induction heating equipment for a wide variety of applications.

Offering comprehensive turnkey solutions to facilitate migration to better

technologies with LUZARS support.

Quote your solution for any industrial application, optimize production times

and reduce costs.

The versatility of Luzars technology for induction heating of forging allows it to be implemented in a wide range of applications for the processing of materials such as aluminum, brass, copper, steel, among others.

Our induction heating equipment makes the process more efficient, achieving a continuous casting of the molten metal; therefore it is feasible to minimize cleaning in the production process.

Our induction process is ideal for generating heat quickly and in a focused way, allowing the continuity of the line by integrating our stations into a continuous, repetitive and automated process.

Our technology is compatible with a variety of solutions such as Luzars reducing atmosphere brazing chamber to keep the part rust-free or our selection of hand-helds specifically designed to bring the machine closer to the process.

Processes such as the manufacture of filters for machines in general, makes the curing of resins by induction with LUZARS power units favorable and together with our conveyor belts, a comprehensive solution suitable for the client is created.

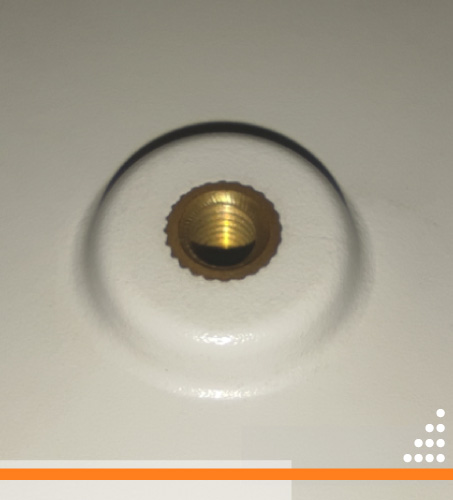

We have dedicated equipment to integrate with plastic injection machines, which are highly adaptable to the needs and requirements of our customers, offering quality and service.

Our technology is ideal for thermo-sealing processes, since localized heat is applied quickly into the area to be sealed; this method is used for many applications, including electronic connectors, thermally activated adhesives, films, among others.

The insertion process becomes agile due to the rapidity in the heating with our equipment, which avoids the formation of oxides and gives continuous production with excellent results.