Specialized Processes

Our focused induction hardening processes are meticulously developed, heated to the exact temperature and cooled with water and polymer giving excellent results.

quenching for steels parting from 0.35% carbon:

SAE 1045

SAE 1050

SAE 1144

SAE 4140

SAE 4150

SAE 4340

SAE 4350

SAE 5150

SAE 8650

SAE 1146

D5506 Nodular Iron

We work with a range of hardness between 40 HRC - 65 HRC (850HV - 400HV) depending on the percentage of carbon.

We develop solutions according to your requirements.

Our induction hardening process begins with the receipt of sample pieces for the specific development of the inductor, thanks to our expert team of engineers, a process is managed according to the client's needs (technical specifications, layer depth, surface hardness, etc.), who constantly verify the quality of the pieces.

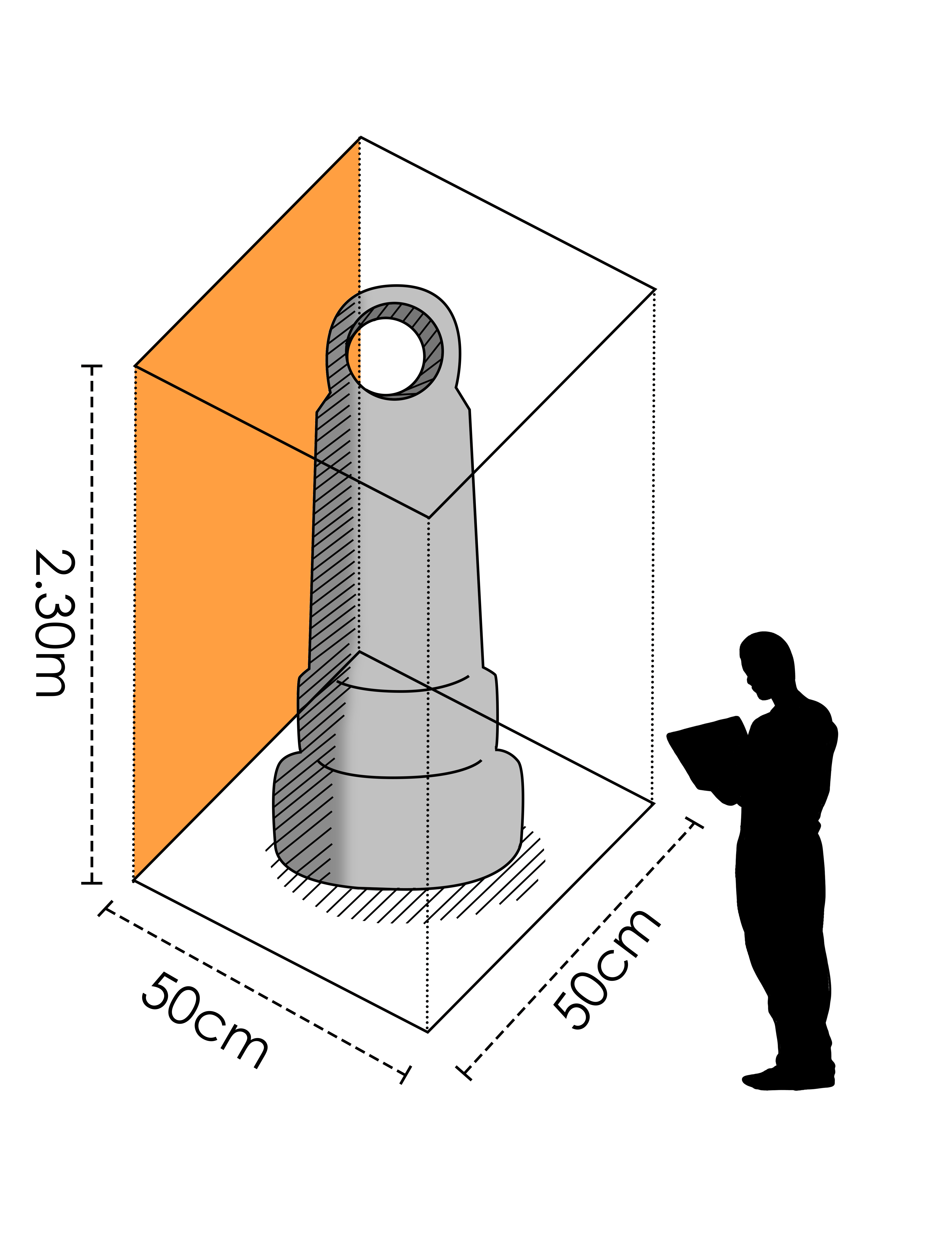

We stand out for our versatility in processes.

Thanks to the fact that we are developers of our technology, we have the advantage and ability to process a wide variety of parts, our processes are extensive including quenching, annealing, stress relieving, normalizing and induction tempering, with the characteristic of being a process selective and highly automated.

Quality distinguishes us

We are proud of our quality management system, which commits us to deliver products with standardized and repeatable processes, from the first piece to the last; in our laboratory we generate the release of the production process through a certified metallurgical report that guarantees microhardness and microstructure.

From small batches to industrial volumes

The induction hardening maquila is a clean and repeatable process, which

stands out against other

traditional methods, there is no contact with the part, it does not use gas

or generates a flame,

avoiding risks to the operator, and the use of aggressive oils with the

environment.

We have fast processes, which allow us to have a production with volumes

ranging from single

batches to industrial sizes, guaranteeing a timely delivery time.